1. Introduction

After twice of "oil crisis" in 1970's, coal moved into the spotlight again as a fuel for power generation. As a consequence of energetic investigation in

1980's on the advanced coal fired power station placing emphasis on environmental compatibility and improvement in thermal efficiency, superiority of

Integrated Coal Gasification Combined Cycle (IGCC or ICGCC) power system over the conventional coal fired power plant was widely recognized in Japan.

In this paper, short history of IGCC R&D since 1970's and the future prospect of IGCC technology in Japan is described.

2. Historical overview of IGCC R&D in Japan

Research and development of IGCC was started in early 1970's in Japan and the air blown gasifier was employed dominantly, considering the simplicity and

the economy of the plant.

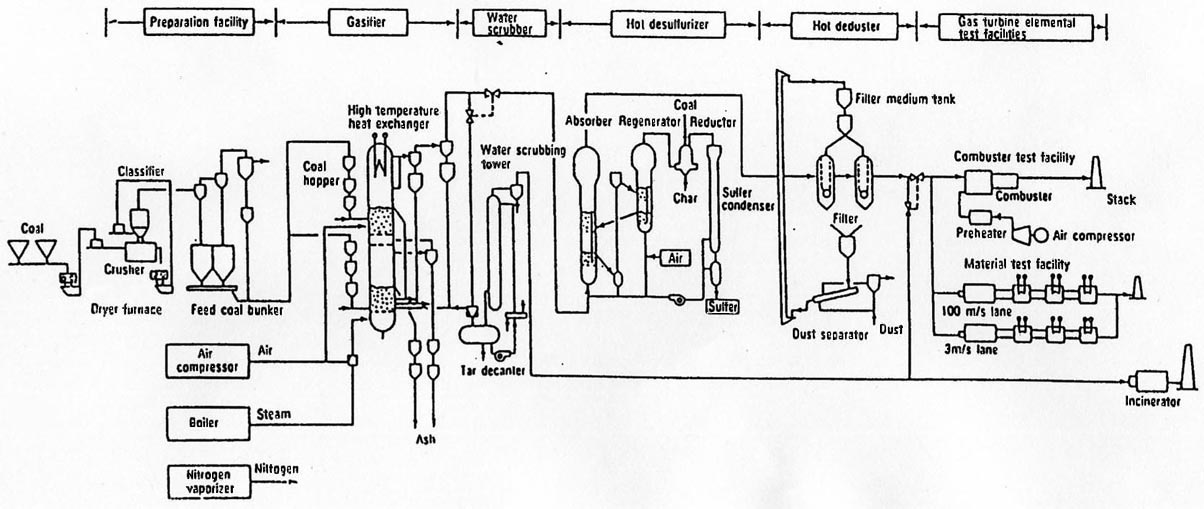

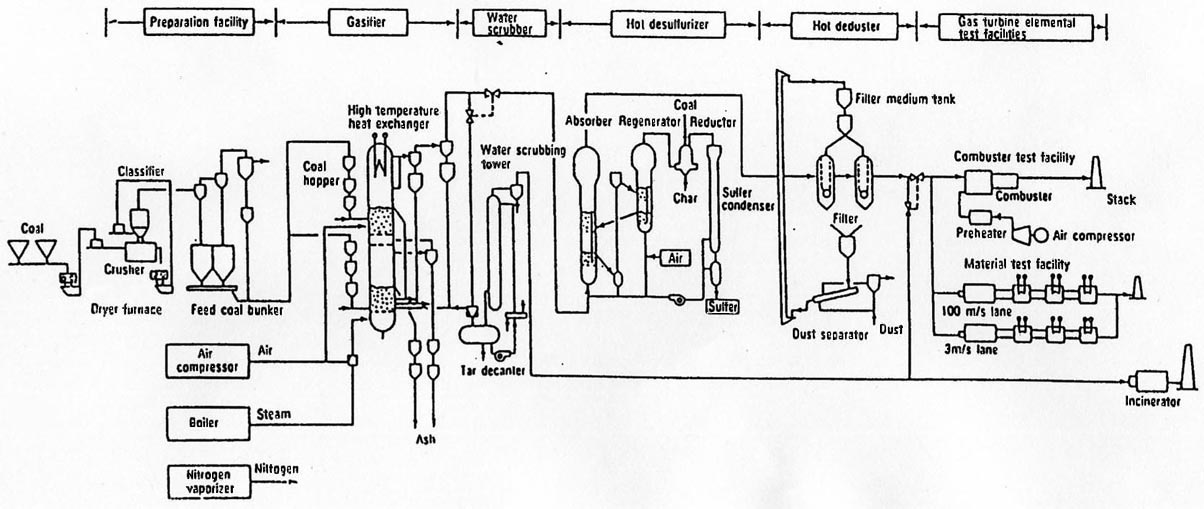

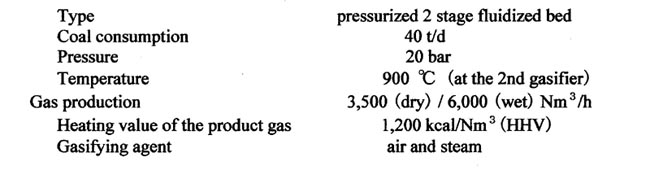

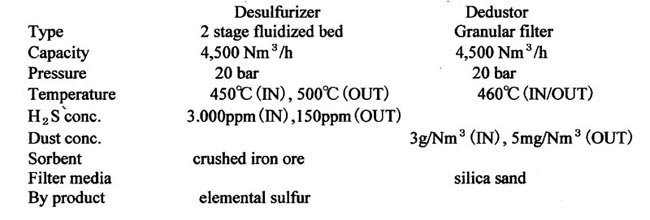

1) R&D at the Coal Mining Research Centre

R&D of coal gasification to produce low heating value coal gas was started in 1974 at the Yubari test field of Coal Mining Research Centre. Followed

by the PDU ( 5t/d) operation from 1975 to 1984, operation test with 40 t/d pilot plant was conducted from 1981 to 1987. Subsequently ,"supporting study of

gas cleanup facility for Nakoso IGCC pilot plant" was conducted until fiscal 1990. Although the main component of Yubari plant is the gasifier and gas cleanup

facility, as shown in Fig. 1, they are designed for IGCC. Further, element study of gas turbine for low calorie gas was also conducted here.

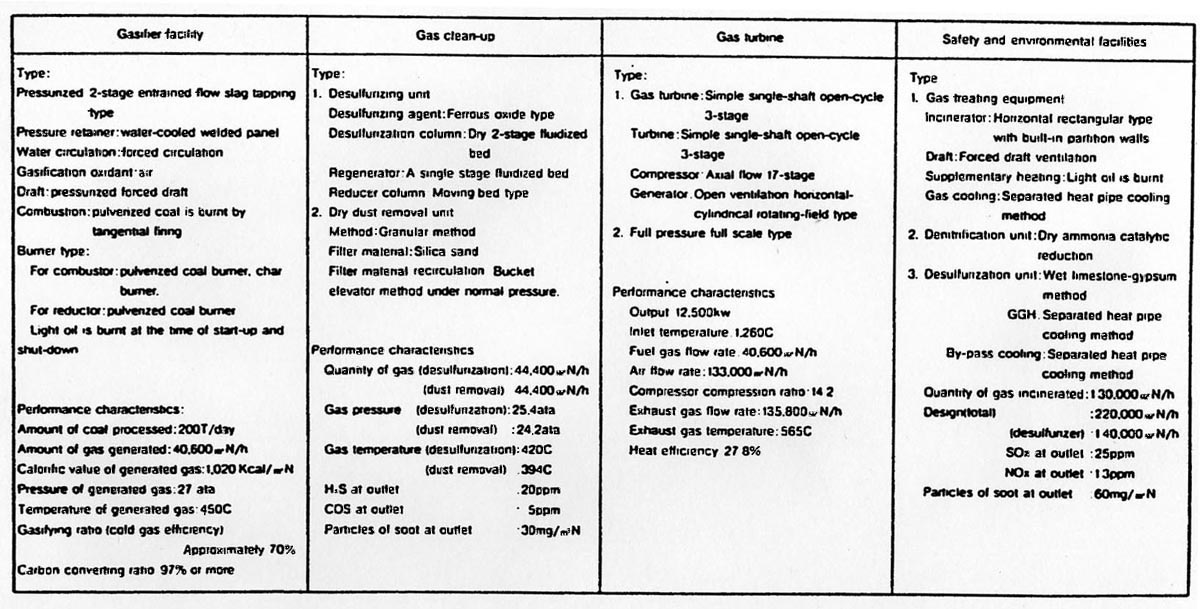

Main specification of the gasifier and the gas cleanup facility are shown in Table 1 and Table 2, respectively.

This gas cleanup unit with fluidized bed desulfurizer and granular filter is employed in the Nakoso IGCC pilot plant.

In addition a feasibility study of the IGCC plant with the coal consumption of 1,000 t/d employing this system was later

conducted by Electric Power Development Company(EPDC).

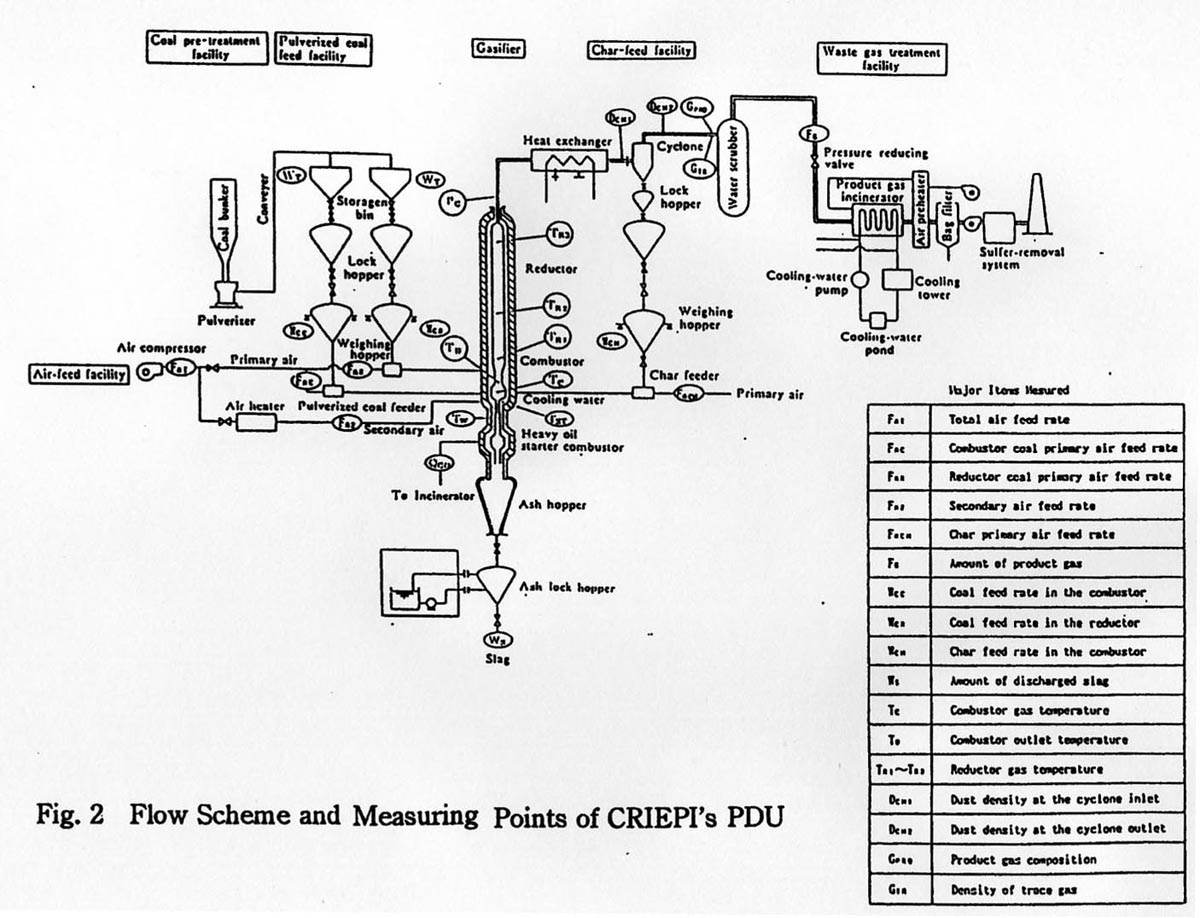

2) R&D at CRIEPI

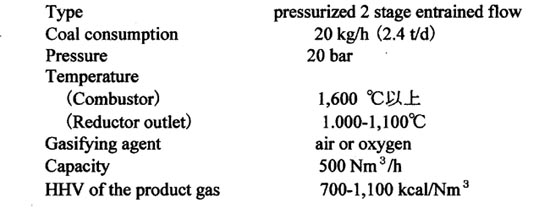

Central Research Institute of Electric Power Industry (CRIEPI) and Mitsubishi Heavy Industry have jointly conducted

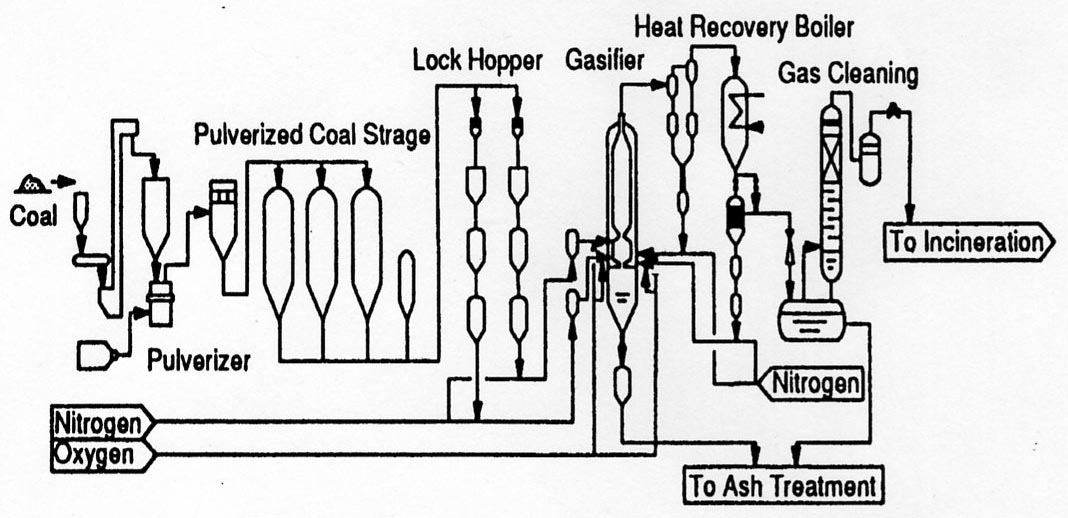

R&D of the entrained flow gasifier since 1982. Main specification of the gasifier and the flow diagram are shown

in Table 3 and Fig.2, respectively. In 1985 they also started the development of a dry (hot) gas cleanup technology.

Although this 2t/d gasifier was originally used as the process development unit (PDU) for Nakoso IGCC pilot plant, it was also utilized for

preliminary testing of coals prior to the gasification test at Nakoso pilot plant.

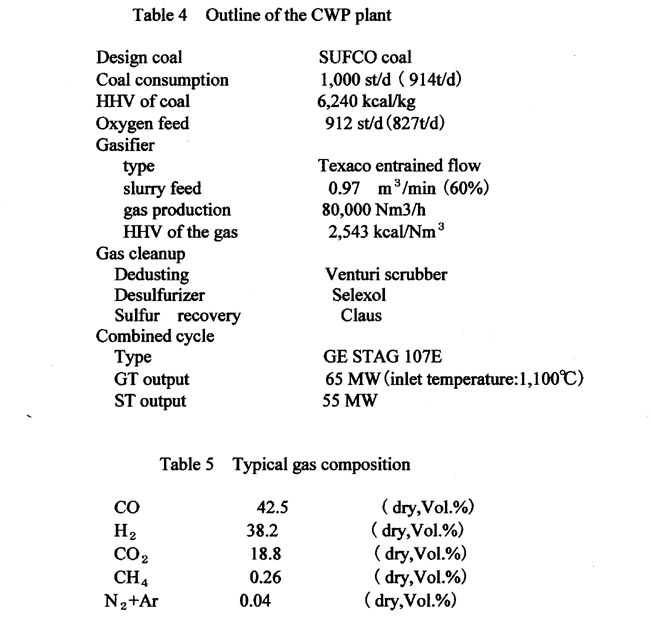

3) Participation in the Cool Water Coal Gasification Program (CWCGP)

In order to obtain technology and general information on IGCC, Tokyo Electric Power Co., CRIEPI, Toshiba and IHI participated

in the CWCGP as a "Participant", organizing a consortium (Japan Cool Water Program Partnership : JCWP). Participants were responsible

for the management of the organization. Other members of the Participant except JCWP were Southern California Edison (SCE), Texaco,

EPRI, GE and Bechtel Power. In addition, ESEERCO and SOHIO participated in the CWCGP as "Contributor (small amount investor)". CWCGP is

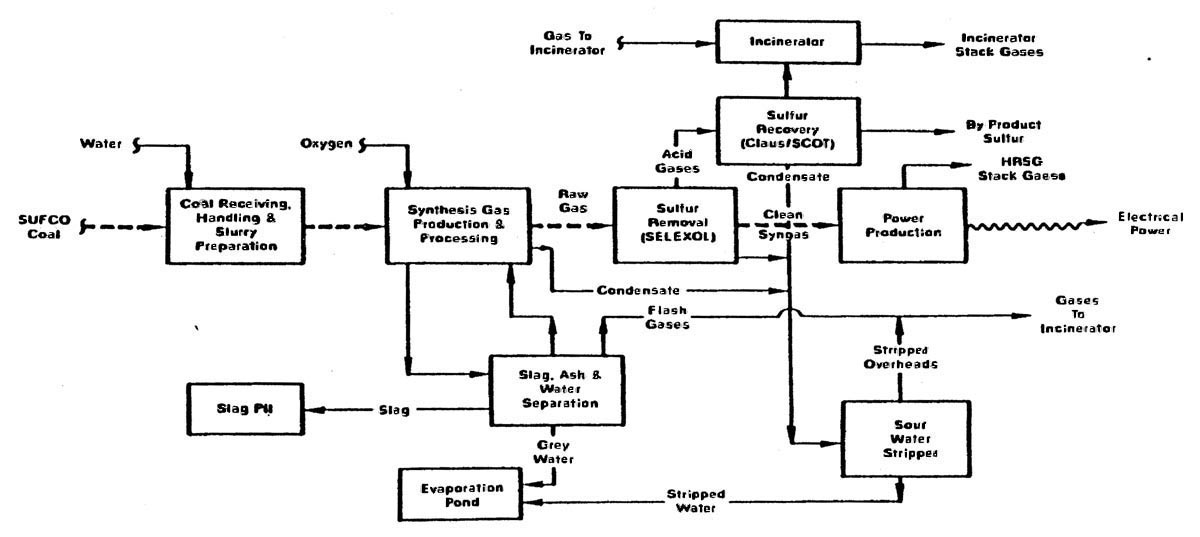

a demonstration project of IGCC with the total project cost of $300 million and the plant was constructed at the site

adjacent to the SCE's Cool Water Power Station. Main specification of the plant is shown in Table 4 and the block flow diagram of the plant is shown in Fig.3.

Typical gas composition of the plant is shown in Table 5.

Cumulative operating time of the plant reached 27,000 hours in 4.5 years of operation from June 1984 to January 1989. Capacity

factor of the plant in 1987 and 1988 reached 70%, although the average value during this period was 58.7%. As the CWCGP plant was a

demonstration plant and its design was not optimized, thermal efficiency of the plant was not high (31.7%). Distinguished achievement

of the CWCGP is that it proved the practicality of IGCC system.

In order to improve compatibility to the stringent environmental requirement and to upgrade the operability of the plant, TEPCO and IHI

have jointly conducted improvement of the gasifier such as the development of "combination burner" and the testing of materials for gasifier

and heat exchanger.

4) Nakoso IGCC project

Although we have obtained a lot of information by participating in the CWCGP, development of more efficient IGCC system was requested

in Japan where most of the energy resource is imported from abroad. And the decision was made to develop an advanced IGCC system by domestic

technologies. Then New Energy and Industrial Technology Development Organization (NEDO) entrusted CRIEPI to conduct a feasibility study(FS).

In this FS, various types of IGCC systems were compared with the cooperation of manufacturers and committee members of each electric power

companies. 8 IGCC systems, namely 4 different types of gasifiers in terms of coal feed system (slurry feed/dry feed) and gasifying agent

(oxygen/air) combined with 2 types of gas cleanup system ( dry/wet), were selected as an object of the study.

As a result of the comparative study, placing emphasis on environmental compatibility and economy, the IGCC systems with dry coal

feed and air blown gasifier integrated with dry or wet gas cleanup unit were highly evaluated. However, considering the future prospect

of the high efficiency system, the IGCC system with dry (hot) gas cleanup unit was finally recommended.

Entrusted by NEDO, Engineering Research Association for Integrated Coal Gasification Combined Cycle Power Systems (IGC Association )

has constructed a 200 t/d IGCC pilot plant in Iwaki city, Fukushima prefecture and conducted the R&D. Test operation of the pilot plant

terminated in success in February 1996, solving the early stage slagging problem of the gasifier by the plant modification. And we are ready

to discuss the next step demonstration plant. Details of the Nakoso project is shown in the ATTACHMENT-I.

Main specification of the Nakoso IGCC pilot plant is shown in Table 6.

5) Other IGCC related project

i) HYCOL / EAGLE project

Entrusted by NEDO, "Research Association for Hydrogen-from Coal Process Development" conducted a R&D of an advanced coal gasification

process with a pilot plant of 50 t/d coal consumption (located in Sodegaura, Chiba prefecture) and successfully completed its three years

of operation program in April,1994. The program proved the fundamental features of the HYCOL coal gasification technology; an entrained flow,

oxygen blown, one chamber with two-step spiral flow multi-burners.

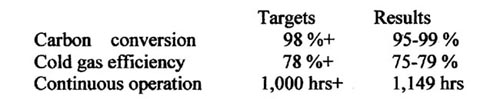

Cumulative operating time logged 2,164 hours, including a 1,149 hour long and uninterrupted run, and four different coals were gasified

during this period.

. Targets of carbon conversion rate (98%+) and cold gas efficiency(78%+) were achieved simultaneously. Problems due to ash component

experienced during the shake down phase were successfully overcome.

Based on the HYCOL process, EAGLE project is aiming at producing gas for fuel cell integrating high efficiency desulfurizer. Currently,

basic design of the plant and the related element study are being conducted. Center for Coal Utilization, Japan (CCUJ) and Electric Power

Development Company (EPDC) are jointly responsible for this project. Total project cost is approximately 22 billion yen , two third of which

is subsidized by the Japanese government.

Major Japanese heavy industries have participated in the leading IGCC projects in Japan and are conducting R&D of related technologies,

putting emphasis on IGCC among various R&D items.

a. IHI

IHI has been conducting air blown gasification, slagging test, etc., with their small Texaco gasifier, as well as participating in Yubari.

and Nakoso projects (desulfurizer).

b. Hitachi

Hitachi has been conducting IGCC related R&D with their various test plants, as well as participating in the HYCOL (gasifier) and Nakoso (GT) projects.

c. MHI

MHI has been conducting R&D of IGCC with their small gasifiers, as well as participating in Yubari (gasifier) and Nakoso (gasifier/gas cleanup) projects.

3. Future prospect

After the successful termination of the test operation of Nakoso IGCC pilot plant in February 1996, construction of the next step "demonstration plant"

is looked forward among the electric utility industry. Thus it was decided to conduct 2 years (fiscal 1997-1998) of feasibility study of the

IGCC demonstration plant, as well as related element study in order to improve the reliability of the system.

Preliminary study (prefeasibility study) has already been started in October 1996 by a newly organized IGCC Working Group composed of engineers

dispatched from several electric power companies, opening an office in the R&D Center of Tokyo Electric Power Company.

In the final stage of this prefeasibility study, a few promising systems among several recommended systems by manufacturers and engineering

companies will be selected. And detailed study will be conducted on the selected 3 or 4 systems during the feasibility study of fiscal year 1997-1998.

In this case, scope of the study is not limited to the system adopted at Nakoso pilot plant but open for the best available technologies for

demonstration plant (eg. oxygen blown gasifier, wet gas scrubber etc.), so as to cope with stringent environmental regulation.

Plant capacity is supposed to be in the range of 150-450MW class. Gas turbine is designated to have the inlet temperature of around 1.300℃.

Items of the element study scheduled in 1997 and 1998 wil be decided within this fiscal year( until the end of March next year).

At the final stage of the FS (1998), one of the following decision will be made.

1) Implementation of the demonstration project

2) Postponement of the demonstration project

3) Abandonment of the demonstration project (including direct introduction of commercial plant)

4. Conclusion

Superiority of IGCC power system over the conventional power system in terms of high efficiency and environmental compatibility has widely

been recognized in recent years. Remaining problems are its economy and reliability.

Economic competitiveness can be acquired by adopting gas turbine with higher efficiency and larger capacity. And accumulation of operating

experience of demonstration would be indispensable for the improvement of reliability.

Finally, early commercialization of IGCC system throughout the world is strongly expected in order to use abundant, but still with limited

deposit, coal efficiently.

References

1) J.W.Shih : 1st ANRE/DOE Joint Technical Meeting on Surface Coal Gasification,(1989)

2) David M.Rib : 8th EPRI Coal Gasification Contractor's Conference, (1988)

3) Saburo Hara, et al : Second JSME-KSME Thermal Engineering Conference, 1, 243(1992)

4) Noboru Takanari:The Thermal and Nuclear Power 42, 80(1991)

5) Shigemitsu Araki and Yoshiharu Hanai : Journal of Japan Institute of Energy,75, 839(1996) ------ATTACHMENT-I

6) Toshihiro Yamada,Kazue Nagata,Tomoyuki Hiza : ISA / 96, Advances in Instrumentation and Control,51, 1307

7) Fumiki Ueda and Noboru Yoshida : Journal of Japan Institute of Energy, 74, 731(1995)